- +91 98795 14356

- sales@steeledge.net

- Mon-Sat: 10:00 AM - 7:00 PM

Standerd Series

Steeledge India

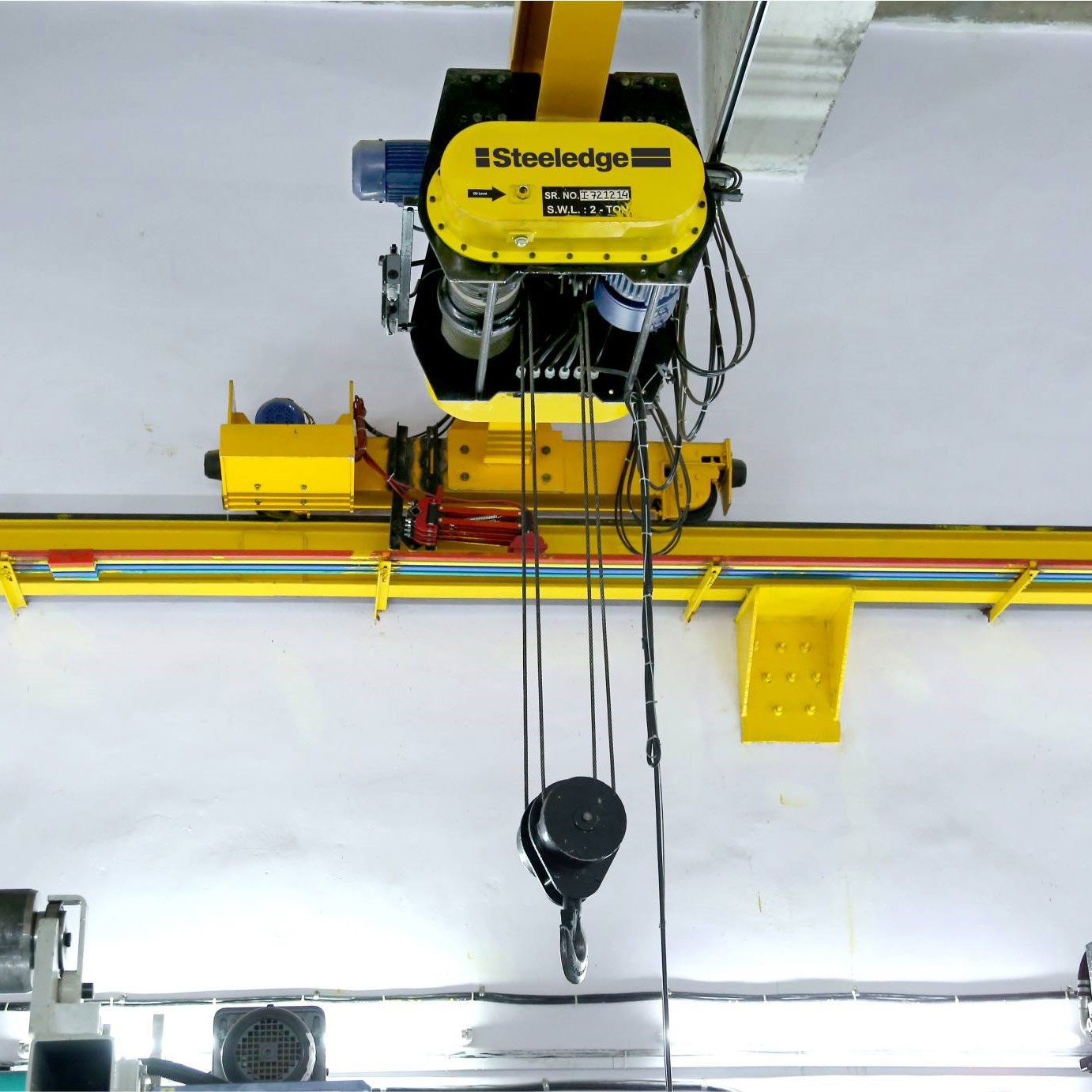

STANDERD SERIES

SteelEdge heavy duty & High-Speed Hoists are best suited for rugged performance. Wire Rope Drum is fixed during a welded one-piece drum housing which is machined in one setting to make sure smooth running of rope drum. Welded drum housing also nullifies skewing effect Drum housing plates aren’t aligned with one another. As both the plates are fixed with long distance bolts in other sorts of Hoist, Drum housing plates as fixed with long distance bolts aren’t aligned with one another perfectly. this is often not the case with SteelEdge Brand Wire Rope Hoists.

SteelEdgeHoists are designed in accordance with IS 3938-1983 modular construction for simple maintenance as brake Motor Gear box instrument panel are easily accessible reducing down time for maintenance.

Alloy Steel spur & Helical gears running on antifriction Ball Bearings reduces noise & increase lifetime of gear box. Motor as per IS 325 with fail safe brake is employed to make sure full safety at any load position even in power outage. Wire Rope confirming to IS 2266, Forged hooks as per IS: 8610 & push stations operate at 24 Volts only.

SteelEdge hoist can also be built with micro speed arrangement (10% of normal Hoisting speed) Higher Speeds, & Life at an additional cost.

- They are fitted with top and bottom “Forged Carbon Steel” safety hooks to resist fracture under excessive load

- Load chain made of Alloy Steel Grade 80 as per IS :3832 is used in all of our blocks

- Heavy Duty Pawl is provided with the ratchet disc and disc break for appropriate locking mechanism and safety

- To ensure safety and long life, all the load bearing parts are heat treated

- Properly sealed gears and brake protects them against damage from dust and corrosion

- Load sheave is machined precisely and mounted on ball bearing for proper working of the block

- Smooth passage of load chain with machined guide rollers ensures optimum efficiency of the Chain Pulley Block

- Before it is dispatched for use by clients, each M3-Series Chain Pulley Block is tested at 150% of the rated capacity

- Safety factor of load chain is 6 times of the rated capacity which complies with the IS Standards

- We recommend them for Mechanism Class-III use where in average the working hours are not more than 3 Hours/Day and they usually have a lifetime

- Designed & Constructed, to offer higher lifetime of the equipment.

- Designed & Constructed, to offer higher lifetime of the equipment.

- Designed & Constructed, to offer higher lifetime of the equipment.

- Designed & Constructed, to offer higher lifetime of the equipment.

- Designed & Constructed, to offer higher lifetime of the equipment.

- Designed & Constructed, to offer higher lifetime of the equipment.

- Designed & Constructed, to offer higher lifetime of the equipment.

- Designed & Constructed, to offer higher lifetime of the equipment.

- Designed & Constructed, to offer higher lifetime of the equipment.

- Designed & Constructed, to offer higher lifetime of the equipment.

- Designed & Constructed, to offer higher lifetime of the equipment.

- Designed & Constructed, to offer higher lifetime of the equipment.

- Designed & Constructed, to offer higher lifetime of the equipment.